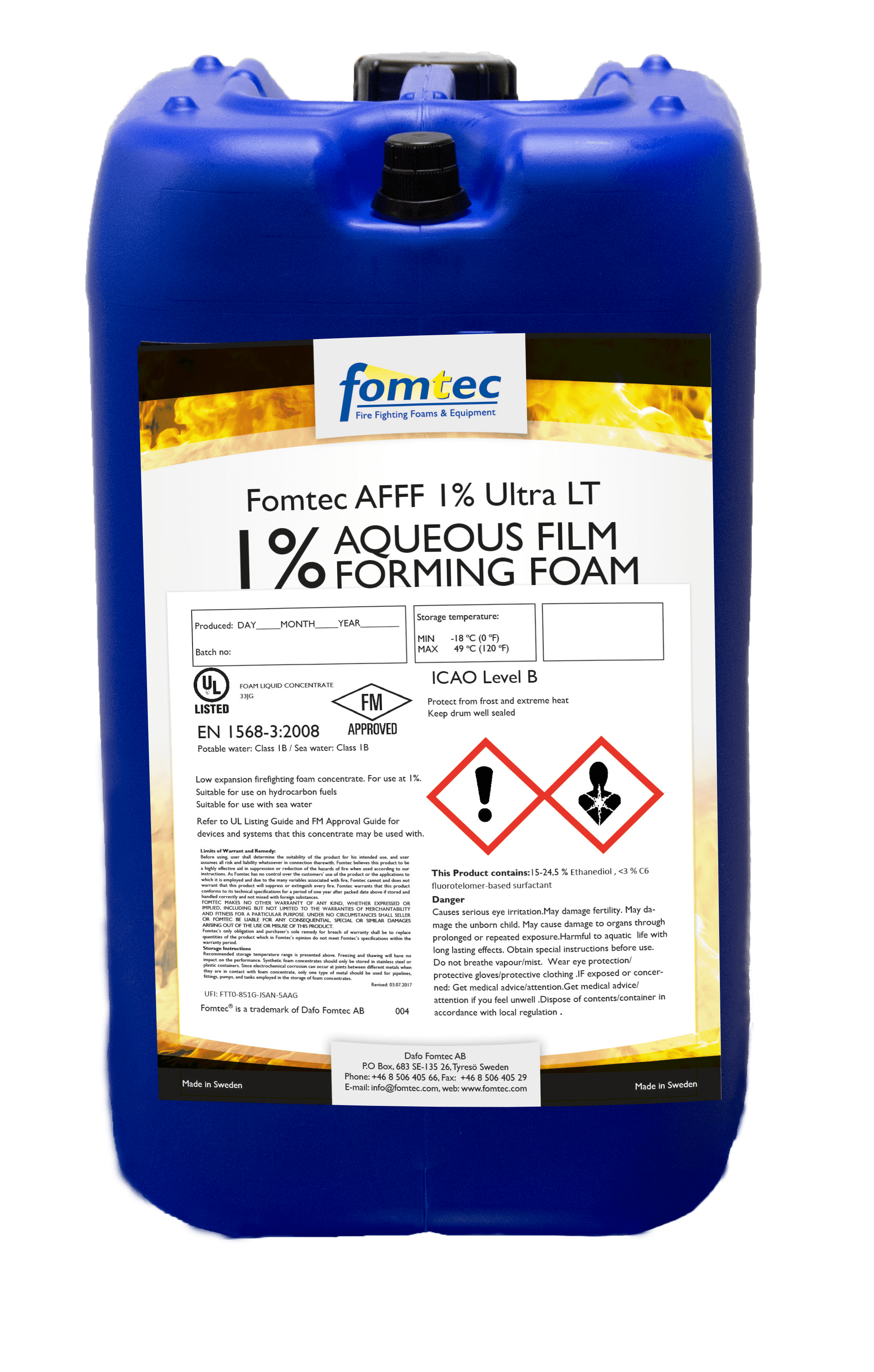

AFFF 1% Ultra LT

Fomtec AFFF 1% Ultra LT is an aqueous film forming foam concentrate (AFFF) consisting of a blend of fluorocarbon-, hydrocarbon surfactants and various solvents and stabilisers

View our other product catagories

AFFF 1% Ultra LT

Overview

Fomtec AFFF 1% Ultra LT is a high-performance aqueous film-forming foam (AFFF) concentrate formulated with C6 Pure fluor surfactants. This blend ensures rapid fire suppression and environmental compliance. The foam's unique film-forming properties effectively cut off the oxygen supply to fires, while its oleophobic characteristics create a stable foam blanket to prevent reignition.

Key Features

- Short-Chain C6 Pure Fluor chemistry: Utilizes advanced fluor surfactants for enhanced safety and environmental compliance.

- Comprehensive Approvals: Meets international standards, including EN 1568, UL 162, ULC, FM 5130, ICAO Level B, and GOST.

- Freeze Protection: Suitable for use in temperatures as low as -38°C, ensuring reliability in cold environments.

- Versatile Application: Effective against both Class A (wood, paper, textiles) and Class B (hydrocarbon fuels) fires.

- Low and Medium Expansion Foam: Ideal for various firefighting scenarios, including sprinkler systems and ARFF vehicles.

Applications

Fomtec AFFF 1% Ultra LT is designed for high-risk installations requiring low proportioning ratios, low freezing points, and high fire ratings. Typical applications include:

- Petrochemical and Chemical Plants: Protection against flammable liquid fires.

- Tank Farms: Safeguarding large storage areas for fuels and chemicals.

- Warehouses: Fire suppression in storage facilities.

- Foam Sprinkler Systems: Integration into fixed firefighting installations.

- Airports and ARFF Vehicles: Compliance with ICAO Level B standards for aircraft rescue and firefighting.

Typical Properties

- Appearance: Pale yellow liquid

- Specific Gravity at 20°C: 1.050 ± 0.020 g/ml

- Viscosity at 25°C (spindle #2, 60 rpm): 15 ± 5 mPa·s

- Viscosity at 20°C (spindle #2, 60 rpm): 20 ± 5 mPa·s

- Viscosity at -18°C (spindle #2, 60 rpm): 220 ± 10 mPa·s

- Surface Tension: ≤ 19 mN/m

- pH: 7.9 – 8.9

- Freezing Point: -38°C

- UL-Listed Temperature Range: -18°C to 49°C

- Recommended Storage Temperature: -37°C to 55°C

- Suspended Sediment (v/v): < 0.1%

Storage and Shelf Life

When stored in original, unbroken packaging, Fomtec AFFF 1% Ultra LT has a shelf life exceeding 10 years in temperate climates. Shelf life is dependent on storage temperatures and conditions. For storage recommendations and material compatibility, please refer to Fomtec Technical Advice FTA 10.

For more detailed information, please visit the Fomtec.

If you have any questions, require further details about our products, or need assistance with placing an order, please feel free to contact us. Our team is here to help and ensure you have all the information you need.

Reviews

There are no reviews yet.